Description:

The carbon particle generator is my senior capstone project. The task is to design and manufacture a system that contains a laminar flow flat flame burner for carbon particle pyrolyzation. To achieve this, a liquid hydrocarbon, Decane, is injected coaxially into the center of the methane fueled burner. Through the heat produced by burning methane gas, Decane is pyrolyzed and split into its base elements, primarily solid carbon and hydrogen gas. These carbon particles can then be used to transfer heat into the working fluid of a heliostat or similar solar system more efficiently.

Contribution:

As the team lead in this project, my primary responsibilities included provided a framework and plan to keep members on task, and being the primary communication between our team and sponsor in meetings and presentations. To manage the team and distribute tasks more easily I set up a trello, a team collaboration tool and took the lead for many presentations and discussions with our sponsor.

My responsibilities as a team member and engineer included designing the laminar flame burner and providing analysis of the flow conditions through the ceramic and heat transfer throughout the system. These analyses led me to design decisions in both the materials chosen and the required flow conditions to meet the cooling requirements for the water in the cooling passages. CFD including ANSYS, Solidworks flow simulation, and Chemkin pro alongside hand calculations containing both fluid dynamics and heat transfer were used to find design solutions. Pump sizing and heat transfer constraints were designed to meet burner head-loss and cooling conditions. The burner was 100% designed and manufactured on behalf of myself and the rest of our team.

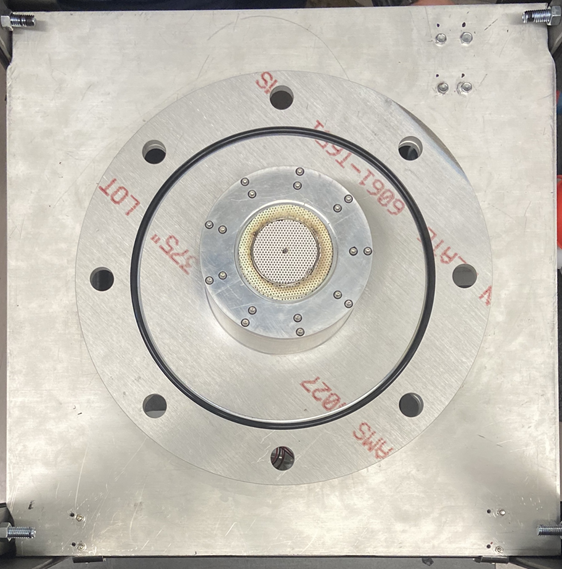

Exploded view of burner

Section view of burner with cooling passages exposed

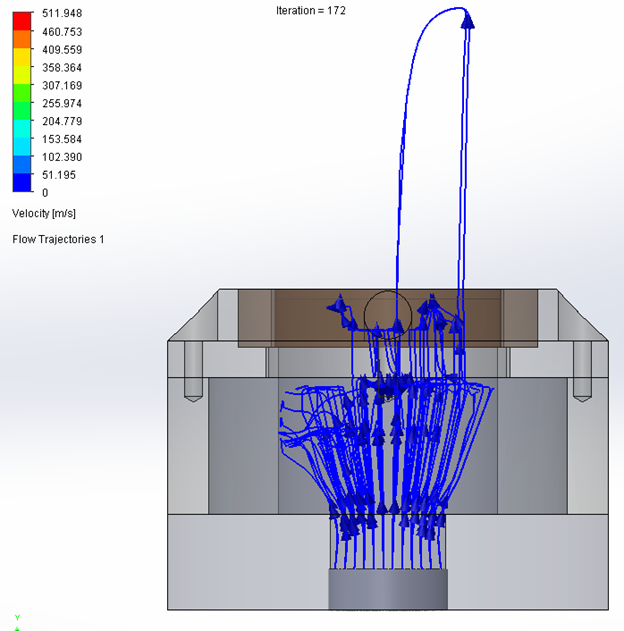

Cross Cut Burner Pressure Streamlines

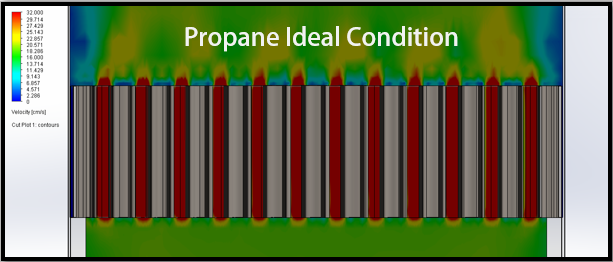

Porous media ceramic Simulations

Desired Porous media Flow Trajectory Obtained

Flame is stable due to optimal gas velocity

Flame Blows off due to high gas velocity

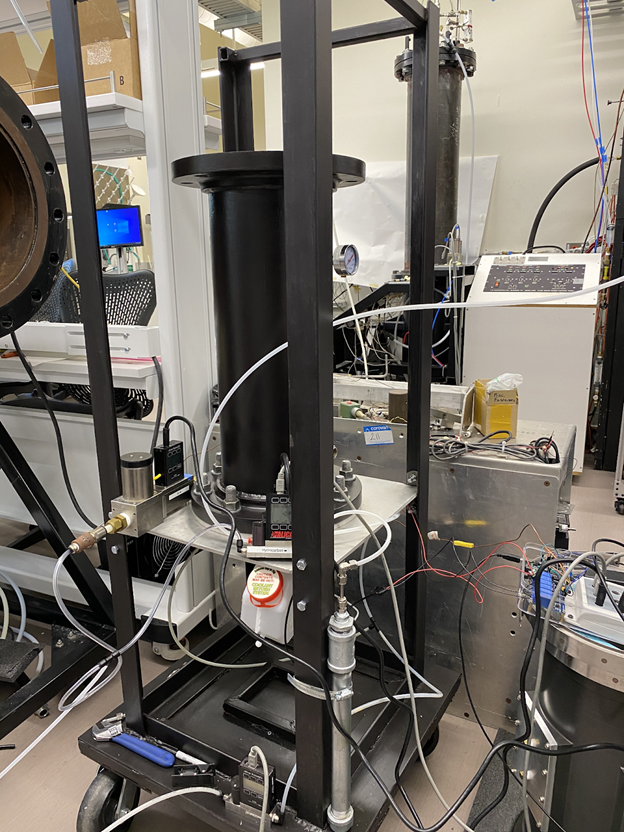

Pressure Chamber Assembly

Full Burner Assembly

Design Day video. Animated and edited in blender and Solidworks animation

Burner running on propane at a lean equivalence ratio.

Burner running on propane at a stoichiometric equivalence ratio.